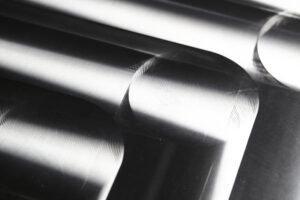

CORTS® CORC-g Verbundstahl

Einzigartig in drei Qualitäten

CORC-g-Standard

Universell einsetzbar 62 +/- HRC

CORC-g-Rostfrei

Für starken Verschleiß 54 +/- HRC

CORC-g-Ganzstahl

Für hohe Lasten Härten entsprechend der Anforderungen

Verschleißplatten aus CORC-g Verbundstahl sind die Lösung.

Globaler Wettbewerb zwischen Wirtschaftlichkeit und Qualität.

Im globalen Wettbewerb stehen Walzwerke vor der Herausforderung, die Wirtschaftlichkeit des Walzprozesses sowie die höchste Qualität der gewalzten Produkte zu garantieren – also gilt es Verschleiß zu minimieren.

CORC-g-Standard kann in nahezu allen Bereichen eingesetzt werden und weist einen sehr hohen Härtegrad der durchgehärteten Verschleißschicht auf.

CORC-g-Rostfrei sollte dort eingesetzt werden, wo zusätzlich zum Reibverschleiß ein hoher korrosiver Einfluss besteht. Unter der Qualität

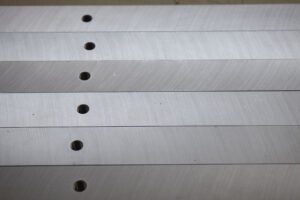

CORC-g-Ganzstahl fertigen wir aus ausgesuchten, sonderlegierten Werkzeugstählen hochbelastete Führungselemente wie Druckmessdosen und Pendelplatten, Führungsleisten für Werkzeugmaschinen bzw. Automationsanlagen für hohe Lasten. Die Härte der Gleitoberflächen beträgt, je nach Werkstoff, 56 bis 62 HRc (durchgehend ohne Härteabfall) und die Stärke dieser durchgehärteten Schicht beträgt ca. 25 Prozent der Gesamtmaterialstärke.

Präzisions-Flachführungen aus CORC-g-Verbundstahl

Der Verschleiß wird aufgrund der harten, abrasions- und korrosionsgeschützten Gleitoberfläche deutlich minimiert. Der Trägerwerkstoff ist ungehärtet und weist eine geringere Festigkeit auf als der Gusswerkstoff der Baustücke oder Walzenständer. Ein entscheidender Wettbewerbsvorteil für jedes Walzwerk.

Unsere CORG-g-Standard kann in nahezu allen Bereichen eingesetzt werden und weist einen sehr hohen Härtegrad der durchgehärteten Verschleißschicht auf

Unsere rostfreies Verbundmaterial sollte dort eingesetzt werden, wo zusätzlich zum Reibverschleiß ein hoher korrosiver Einfluss besteht.

Unter der Qualität „CORC-g-Ganzstahl“ fertigen wir aus ausgesuchten, sonderlegierten Werkzeugstählen hochbelastete Führungselemente wie Druckmessdosen und Pendelplatten, Führungsleisten für Werkzeugmaschinen bzw. Automationsanlagen für hohe Lasten.